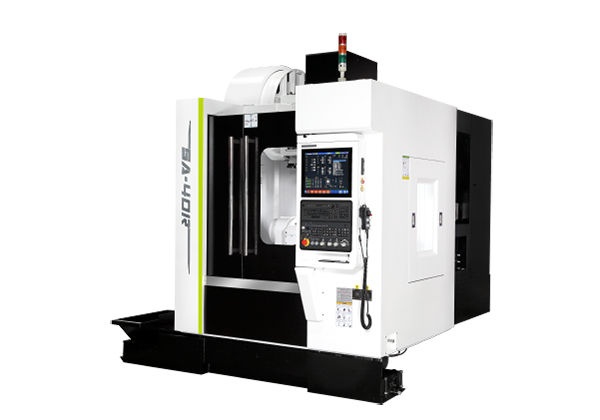

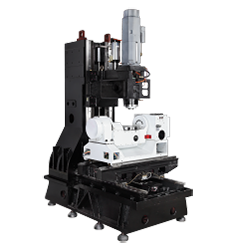

MGPS (Micro-Grade Process and Standard) and High Efficient Spindle

μ-grade accuracy performance, 24hrs spindle operation

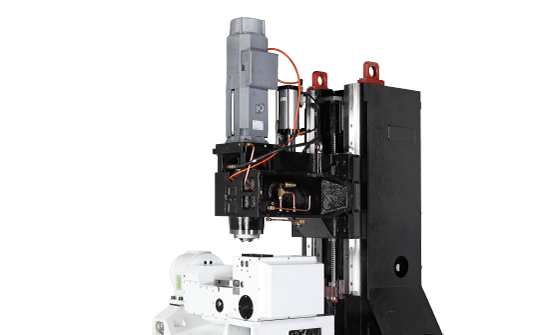

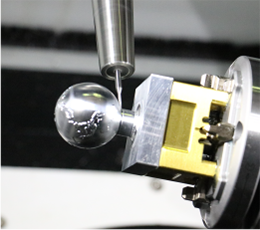

1. High quality self-made spindle to ensure spindle run-out within 5μm.

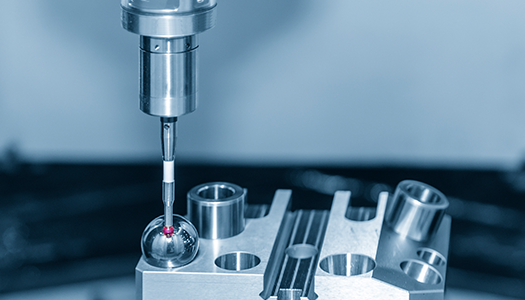

2. Oil-air lubrication spindle:Spindle bearing is lubricated by lubrication oil, spindle is capable of long term running.